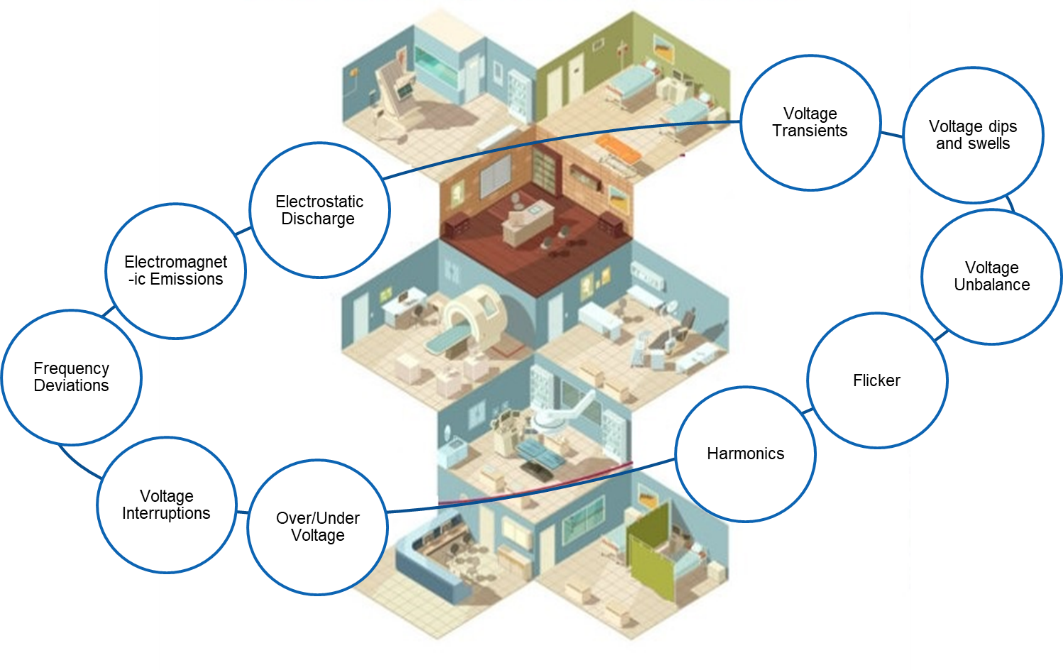

When it comes to electrical safety, earthing is always the first line of defense. Humans and equipment that are connected to or come into touch with an electrical system require a trustworthy Earthing system, which is understood and acknowledged.

The LV's reliability is a critical component of electrical safety and stability. The Earthing system must be constructed in such a way that it is not required to be maintained.

Though the methodology of Earthing has been well defined for MV and HV systems, there are a lot of misconceptions and myths about the practices adopted in the LV grounding systems.

Earth system design on the LV side takes into consideration several aspects of the soil resistivity, fault current, current density on the surface of the electrode etc. The design resistance value of the LV earth system is important because the relay settings and coordination are finalized based on the fault currents which depends on the earth resistance value. Although a ground system, when initially installed, has low earth ground resistance value, the resistance of the Earthing system can increase if the earth rods are corroded.It is not easy attending to an earth electrode that is in service. A dangerous potential may rise.

Further over a period of time, if the earth resistance value changes /fluctuates, the relay settings become invalid, seriously compromising the safety of the installation. Further, in many large industries, it is difficult to locate the earth pits as the area gets covered during subsequent expansion, road formation etc.

At the same time, most sectors have advanced electronics and significant levels of automation. As a result, the LV grounding system must be manufactured in such a way that it requires little or no maintenance over time.

In India,The concept of maintenance free Earthing is gaining popularity in India while at the same time the Maintenance free concept is being more misunderstood.

Below are few facts Dispelling Myths & Ensuring a Reliable LV Grounding System

|

Myths |

Facts |

|

Use of Copper Electrode helps to obtain a low resistance |

The type of Metal used has no significance on the earth electrode resistance. None of the formulae given in any of the international standards factors in the type of metal in a calculation of the earth resistance. However, in highly corrosive areas, it is recommended to use Cu or Cu coated electrodes which have better resistance to corrosion as compared to GI/Steel electrode. |

|

Low resistance can be obtained by using a special electrode |

As per IEEE80, IS3043 and BS7430, the resistance can be lowered only be altering the medium adjacent to the electrode which is backfill material and not the electrode itself. |

|

Resistance to Earth Electrode with or without highly conductive backfill will remain the same |

In fact, there is an improvement of over 31% in value of resistance by using carbon-based backfill. |

|

The instrumental /electronic earth in a facility shall be maintained separately than electrical earth |

As per IEEE 142 & IEC 61000, if the electronic and electrical equipment earthing are maintained separately, dangerous overvoltage may be induced in the system during lightning /severe fault conditions, causing catastrophic failure of electronic equipment. |

|

Neutral of the source transformer and the Lightning Protection Earth must not be connected to the general Earth Grid |

BS7430, IEC 61000, IEEE 80 & IEEE 1100 recommend interconnection of Lightning Protection System earthing with the general earthing grid. Also IS3043 vide clause 22.1.3 & 22.3.1 recommends the adoption of Protective Multiple Earthing System for all installations with a dedicated source transformer. |

For more information, contact us at [email protected]"