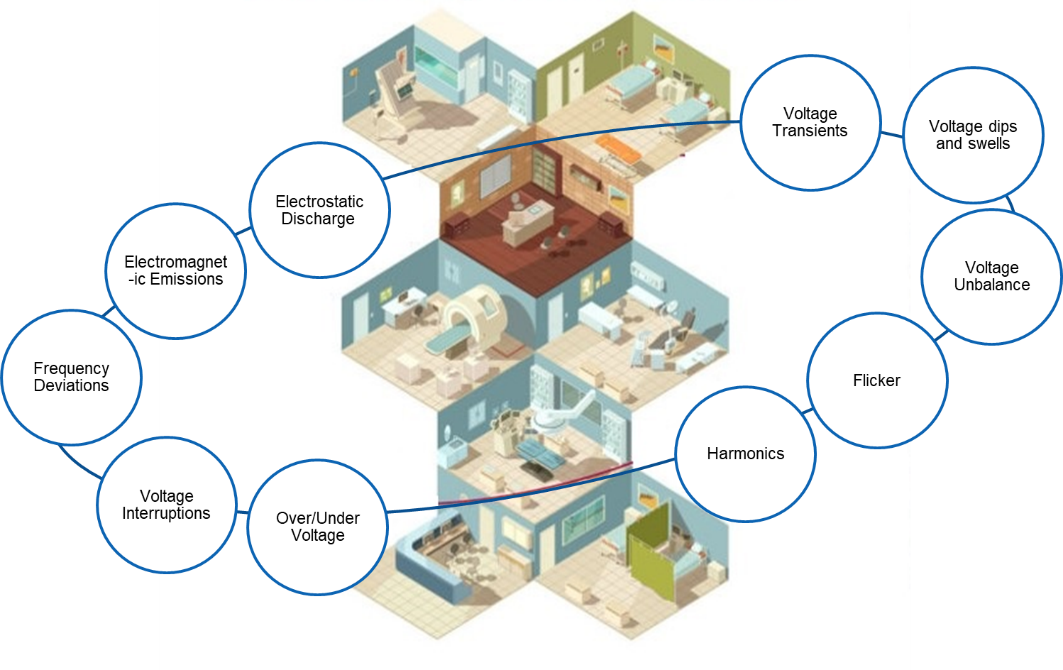

Types of Earthing/Grounding Systems

There are various types of Earthing, but two most popular types of Earthing/Grounding systems are “TYPE A” also known as TT Earthing and “TYPE B” also known as TN-C-S Earthing.

Type A Earthing (TT Earthing):

- Type A earthing is a conventional grounding approach.

- In this system, each electrical equipment is directly connected to an earth electrode, often using ground rods or plates buried in the ground.

- It is suitable for locations with low fault currents and provides safety and functional grounding, commonly used in residential and commercial settings.

Type B Earthing (TN-C-S Earthing):

- Type B earthing is a more advanced grounding method.

- It combines Type A principles with additional measures to protect against voltage surges and transient overvoltages.

- In this system, the earth terminal is connected to both the supply neutral and the ground electrode.

- It is used in areas with high fault currents, such as critical infrastructure and industrial facilities, to provide enhanced protection against surges and transients, often resulting from lightning or equipment malfunctions.

Concrete Embedded Foundation Earth Electrode (Type "B" Earthing) vs. Soil Embedded Earth Electrode (Type "A" Earthing):

Several factors must be considered when deciding between earth electrodes buried in concrete or in soil (Type "A" earthing). In addition to their reliable conductivity, concrete foundations are ideal for grounding because of their substantial contact area with the soil. For long-term performance, bare metal electrodes buried at least 5 cm into the concrete are recommended since they are corrosion resistant.

- Advantages of Concrete-Embedded Foundation Earth Electrodes:

- Minimal Excavation: They eliminate the need for additional excavation, making them cost-effective.

- Weather Resilience: Constructed at a suitable depth, they remain unaffected by seasonal weather conditions.

- Effective Soil Contact: They provide efficient grounding by maintaining excellent contact with the soil.

- Extensive Coverage: Covering most of the foundation's surface, they minimize earth electrode impedance for optimal performance.

- Lightning Protection: They serve as a robust earthing arrangement for lightning protection.

- Construction Site Savings: During construction, they can also serve as an earth electrode for the site's electrical installation, reducing the need for temporary electrodes.

- Main Protective Bonding: They can serve as a foundation for the main protective bonding system, aligning with standards.

In cases requiring insulated foundations, alternative measures can be considered, such as additional concrete-embedded foundation earth electrodes below isolated foundations, ring earthing, or, as a last resort, Type A earth rods.

To adhere to the "Global Earthing Concept" described in IS 3043 - Code of Practice for Earthing, it is crucial to connect concrete-embedded foundation earth electrodes from different parts of a single foundation using suitable earthing conductors. For corrosion resistance, use only stainless-steel electrodes directly installed from the foundation concrete into the soil, avoiding hot-dip galvanized steel.

Before pouring concrete, a qualified individual should conduct a survey and create documentation records of the associated reinforcement. This information should be included in the overall electrical installation document to ensure compliance with safety and quality standards.

Please let me know if you need further assistance or have any requirements [email protected].