A good earthing system and earthing maintenance is an essential element of any electrical system, it requires for safety and reliability reasons.Fundamentally, every electrical installation is required to have a good and reliable earthing system. Good earthing systems is important for

- Safety of human and animal life

- Limiting damage to electrical equipment incase of fault / lightning

- Timely operation of the protective devices

The resistance of an earth electrode purely depends on the soil resistivity and type of electrode used.

Conventionally, for earthing, a cast iron plate / GI pipe is used as an electrode. The pit is excavated and the electrode is placed in the centre and is filled with soil, mixed with salt and charcoal. The conduction of current in the conventional electrode is electrolytic. Hence, regular watering and charging of the earth pit with salt is very essential to maintain low earth resistance.

Regular Maintenance of the Earth Electrodes is becoming a challenging preposition due to the following reasons.

1. A typical installation requires 4 types of Earthing (Safety, System, Electronic & Lightning)

2. In many commercial projects in the cities, the earthing is possible only in basements.

3. In projects, where the open area is used for earthing, landscaping is done, completely sealing / hiding the earth electrodes.

4. Even where the electrodes are accessible, willingness to maintain is either lacking or not happening.

Moisture plays a very crucial role in the resistance of the electrode. India being a tropical country, where close to 9 months is dry season, making necessary provision for watering as recommended in Indian standards is challenging.

Even to raise the moisture content to 5% in dry season, a single earth pit needs around 4000 liter of water which is impossible to provide with so much scarcity.

Watering an electrode and charging it with salt is not done regularly due to these practical limits, and the salt provided dissolves over time due to rain (in many places, within 2-3 years). As a result, the resistance rises, and the earthing becomes useless.To sum up, the limitations in Conventional Earthing system are:

- No standardization – Neither in electrode nor in backfill

- Commercial grade Cast Iron plate / GI pipe is used as electrode in most cases

- The backfill (SALT) reacts with the electrode and causes corrosion

- The salt dissolves in water and conductivity dips over time thereby increasing the resistance.

- Not suitable for places with high water table, flowing water etc.

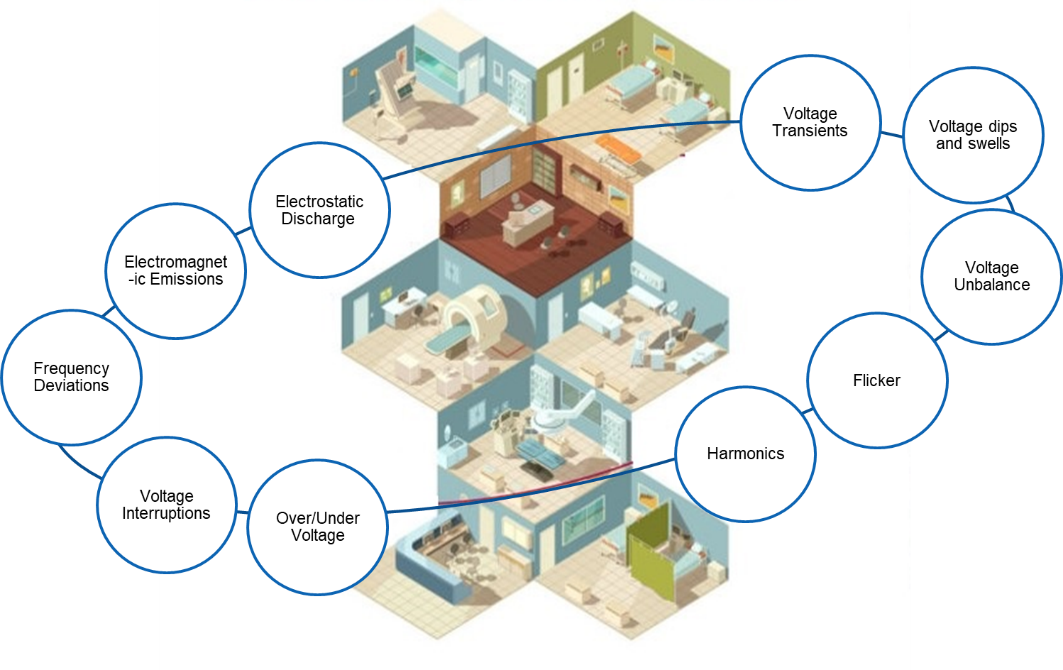

- Nowadays, there is always a residual current flowing through the electrode due to harmonics, imbalance in loads etc., which aids corrosion.

Hence, it is advisable to go in for Maintenance free Earthing Solutions. The Maintenance free earthing is possible by treating the soil surrounding the critical area of the electrode.

WHY SOIL TREATMENT?

The technology to achieve a good earthing mainly depends on the Backfill compound as it influences the critical area around the electrode as mentioned in IEEE 142. The type and quality of Backfill compound determines the long-term reliability of the grounding system. For greater degree of permanence, IEEE/BS standards recommend ground enhancement material or conductive concrete with resistivity of < 0.12 Ohm mtr to be used around the electrode.

The carbon-based ground enhancement materials are permanent and do not leach any chemicals into the ground.

Indian & International standards recognize, that, treating an area of about 75 to 100 mm surrounding the Electrode with ground enhancement materials having low resistivity will significantly reduce the earth resistance, generally in the region of 25 to 40%.

The IEC 62561-7 for backfill compound recommend a series of tests to ensure the compounds do not contain any harmful chemicals.

However, it is also important to test these compounds for conformity to ANSI / NSF 60 standards since 40% of the water requirement in India is met from ground water and hence, it is very important, the backfill compound used for earthing system does not pollute the underground water resources.

A comparison between the various grounding systems is attached for ready reference.

Summary:

The advanced latest Maintenance free earthing system shall comply with all leading international standards like IS 3043, BS 7430, IEC 60364/ 62561 , IEEE 80 (clause 14.5D), ANSI/ NSF 60 . The system generally comprises of steel cored copper bonded electrodes with carbon based conductive concrete backfill Compound having Resistivity of less than 0.1 Ohm meter (when tested as per IEC62561-7) as a backfill material surrounding the electrode and shall not require periodical watering and charging.

For more information, contact us at [email protected]"