MISCONCEPTION ABOUT “DEDICATED”, “INDEPENDENT” AND “ISOLATED” EARTHING

An isolated/Independent earth electrode is nothing but an electrically independent earth electrode; it is distinct by definition from the myth or we typically see.

For safety and functionality, an earthing &grounding system connects certain elements of an electric power system to the ground, generally the Earth's conductive surface.

An electrically independent earth electrode defines as one that is positioned "at such a distance from the nearest electrode that the greatest current likely to pass through one of them does not appreciably affect the potential of other electrodes. “The distance mentioned above is nothing but a distance more than the “sphere of influence”.

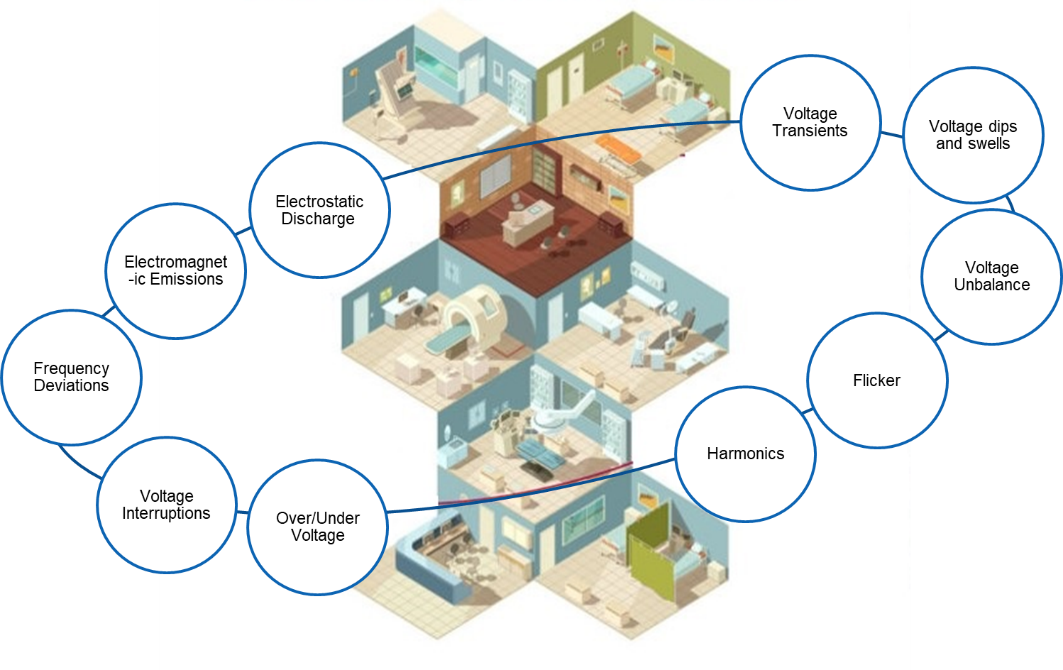

IEC 61000 Electromagnetic compatibility (EMC) - Part 5: Installation and mitigation guidelines - Section 2: Earthing and cabling, I.e IEC 61000-5-2.

Generally, Electronics and Instrumentation Engineers feel that electrical earthing is “dirty earthing” and their equipment will fail if all earthing systems are interconnected. They wish to keep a separate earthing system for their application. Though Electronic equipment can have independent earth electrodes, they should be connected to other earthing systems below the ground.

As per the concept of “Global earthing”, electrical earthing, electronic earthing, instrumentation earthing, communication earthing, structure earthing and lightning protection system earthing, should be interconnected below the ground.

The Concept of isolated earth electrode is not relevant for electronic and instrumentation systems since there are always links with other earth electrodes through (a) soil and (b) through parasitic elements - example capacitance and mutual inductance. Also during lightning or power system fault high transient over voltage develop between this “isolated” earthing system and other parts of the installation which is dangerous for equipment safety, personal safety and electromagnetic compatibility (EMC).

The same is applicable for very low level voltage level signals such as thermocouples whose voltage range is in milli volts. The earthing of these equipment also need to be connected with other earthing system below the ground. This is a recommended practice as per IEC 62305- Protection against lightning- part 4- Protection of Electrical & Electronic equipment inside the structure. In case of earth loop problems, which significantly affect the measurement signal, alternate arrangement is to connect the earthing of such signal to other earthing system using an “earth coupler”, which isolates the earthing under normal conditions and connects during lightning conditions.

Central Electricity Authority - CEA in its 2016 draft version also confirms connecting all earthing systems. "Periodic comprehensive review of the CEA (Measures relating to Safety and Electric Supply) regulations, 2010 (as amended) as below under regulation 37 - Conditions applicable to the installation of voltage exceeding 250 Volts and more detailed under regulation 41 - Connection with Earth for systems exceeding 48 Volts and not exceeding 650 Volts.

All metal works, enclosing, supporting or associated with the installations, other than that designed to serve as a conductor (i.e live & neutral wires of power supply) shall be connected with an earthing system as per standards laid down in the Indian Standards ( IS 3043 , IS/IEC 62305 & IS/IEC 61643-11) in this regard and the provisions of regulation 41.

Here, metal works means enclosures / body of all electrical, electronics, instrumentation, and communication equipment.

For more information, contact us at [email protected]"